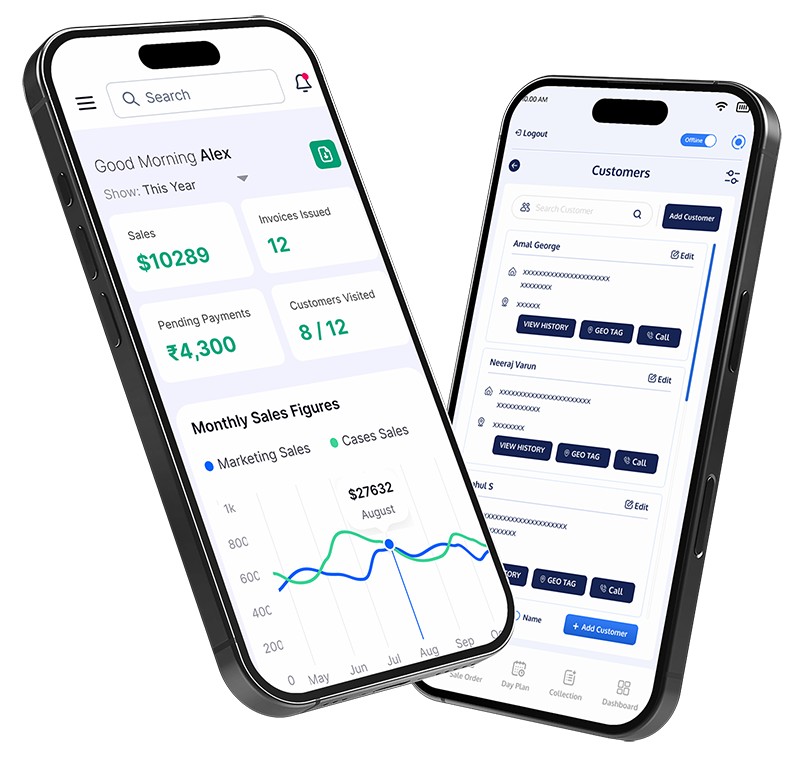

Gain Complete Control Over Stock — From Entry to Exit

Efficient inventory and warehouse management is the backbone of any product-driven business. Our software offers real-time visibility, intelligent automation, and full traceability across your supply chain — ensuring you always know what’s in stock, where it is, and how fast it's moving.

Whether you’re managing multiple warehouses or a single central godown, we help you reduce wastage, prevent stockouts, and make data-backed inventory decisions.